EARTH WORKS

What is Rammed Earthwork?

Rammed earthwork is a construction technique where natural raw materials such as soil, sand, gravel, clay, and sometimes stabilizers (like cement or lime) are compacted (rammed) into a formwork to create solid walls or foundations. This method has been used for centuries in traditional construction and is still applied today for sustainable building projects.

Where It Is Used:

- Retaining Walls – to hold back soil in landscaping or infrastructure projects.

- Foundations and Base Layers – in roads, embankments, and load-bearing structures.

- Sustainable Buildings – as walls in eco-friendly houses or structures.

- Boundary Walls – for rural or traditional property demarcation.

- Embankments and Flood Protection – in large infrastructure and irrigation projects.

Common Issues in Rammed Earthwork Construction:

- Soil Quality Variations – inconsistent soil composition affects strength.

- Moisture Control – incorrect moisture content can lead to weak compaction.

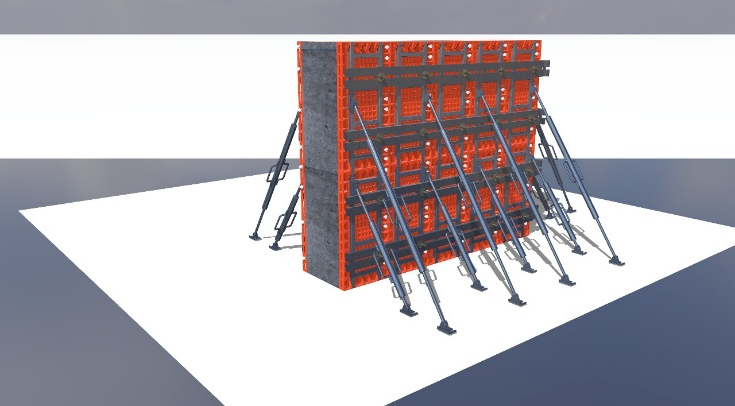

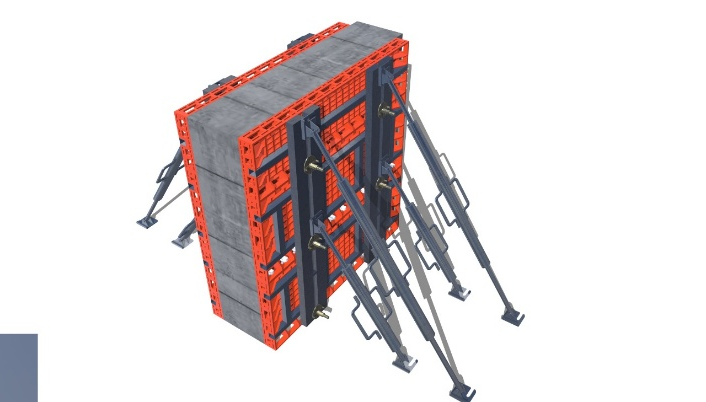

- Formwork Stability – requires strong formwork to hold soil during ramming.

- Weather Sensitivity – rain or excess moisture can damage fresh rammed sections.

- Labour Intensive – traditional ramming requires considerable manual effort.

- Cracking – shrinkage cracks can appear if stabilizers or curing are not properly applied.

- Slow Construction – manual processes and layer-by-layer compaction increase time.

- Durability Concerns – unstabilized rammed earth may erode over time without proper protection.

Issues vs. How Plastic Formwork Helps in Rammed Earthwork Construction

| Rammed Earthwork Construction Issue | Solution | How Plastic Formwork Helps |

|---|---|---|

| Soil Quality Variations | Use stabilized soil mixes (lime/cement) and conduct soil tests before compaction. | Plastic formwork allows controlled layer thickness, helping achieve uniform compaction even with varying soil mixes. |

| Moisture Control | Maintain optimum moisture during ramming to ensure proper bonding. | Smooth, non-absorbent surface of plastic formwork prevents moisture loss, maintaining ideal compaction conditions. |

| Formwork Stability | Use strong, well-supported formwork to resist lateral pressure during ramming. | Plastic formwork has a secure locking system with built-in tie holes, ensuring stability without heavy external supports. |

| Weather Sensitivity | Plan work during dry seasons and cover fresh walls to protect from rain. | Weather-resistant panels do not swell or rust, maintaining integrity even during unexpected weather conditions. |

| Labour Intensive Process | Use mechanized rammers or lighter formwork to reduce manual effort. | Lightweight plastic panels are easy to handle and assemble, reducing labor requirements significantly. |

| Cracking | Add stabilizers and ensure proper curing to minimize shrinkage cracks. | The smooth finish of plastic formwork ensures even compaction, reducing weak spots and minimizing crack formation. |

| Slow Construction | Use modular formwork and mechanized tools to speed up construction. | Modular plastic panels allow quick assembly, dismantling, and reuse, accelerating construction time. |

| Durability Concerns | Apply protective coatings or stabilizers to enhance wall longevity. | High-quality finish from plastic formwork reduces surface erosion and improves durability when combined with stabilizers. |

| Difficulty in Shaping Walls | Traditional wooden formwork limits flexibility in shapes and sizes. | Plastic formwork’s modular design allows easy adjustment of wall heights and widths without additional fabrication. |

| High Cost of Maintenance | Regular maintenance of timber/steel formwork increases project costs. | Plastic formwork can be reused 100+ times, lowering costs and requiring almost no maintenance. |

Summary

Plastic formwork improves rammed earthwork construction by offering:

- Stability and Secure Locking during ramming.

- Easy Handling and Modular Adjustments for different wall dimensions.

- Weather Resistance and Smooth Finish, enhancing wall quality.

- Cost-effectiveness with 100+ reuses and minimal maintenance.

- Reduced Labour Dependence due to lightweight panels and simple assembly.